Tap Gorchudd Aml-Bwrpas Meiwha

Manteision cynnyrch:

1. Tapiau edau dur cyflymder uchel premiwm gyda gorchudd nitrid, caledwch arwyneb, crafiad, a gwrthsefyll cyrydiad wedi'i wella'n fawr.

2. Tap pigfain troellog, tynnu sglodion yn gyflym i lawr a phrofiad tapio llyfn ar gyfer tyllau trwodd, gwych ar gyfer torri edafedd newydd neu atgyweirio edafedd sydd wedi'u difrodi.

3. Gellir defnyddio set dril tap edau sgriw gyda wrenches tap llaw, gweisg dril,peiriannau tapio, peiriannau CNC a melino, yn ddefnyddiol ar gyfer tapio cyflym a manwl gywir.

4. Offeryn tapio edafu, drilio twll cyflawn, tapio dadlwthio a gwrth-suddo ar wahanol ddefnyddiau megis platiau aloi alwminiwm, platiau copr, haearn, dur cyffredinol ac yn y blaen.

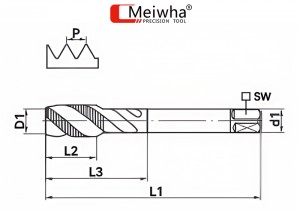

Tap troellog ISO Meiwha:

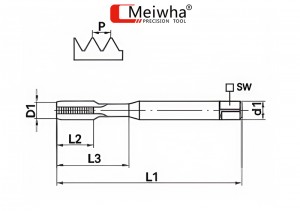

| RHIF y Gath | d1 | p(mm) | d2(mm) | SW | dk(mm) | l1(mm) | l2(mm) | l3(mm) |

| M2*0.40 | M2 | 0.4 | 3 | 2.5 | 1.6 | 40 | 6 | 15 |

| M2.5*0.45 | M2.5 | 0.45 | 3 | 2.5 | 2.05 | 44 | 6 | 16 |

| M3*0.50 | M3 | 0.5 | 4 | 3.2 | 2.5 | 46 | 6 | 19 |

| M4*0.70 | M4 | 0.7 | 5 | 4 | 3.3 | 52 | 8.4 | 20 |

| M5*0.80 | M5 | 0.8 | 5.5 | 4.5 | 4.2 | 60 | 9.6 | 24 |

| M6*1.00 | M6 | 1 | 6 | 5 | 5 | 62 | 12 | 29 |

| M7*1.00 | M7 | 1 | 6.2 | 5 | 6 | 65 | 12 | 33 |

| M8*1.25 | M8 | 1.25 | 6.2 | 5.5 | 6.8 | 70 | 15 | 37 |

| M10*1.50 | M10 | 1.5 | 7 | 5.5 | 8.5 | 75 | 18 | 41 |

| M12*1.75 | M12 | 1.75 | 8.5 | 6.5 | 10.2 | 82 | 21 | 48 |

| M14*2.00 | M14 | 2 | 10.5 | 8 | 12 | 88 | 26 | 48 |

| M16*2.00 | M16 | 2 | 12.5 | 10 | 14 | 95 | 26 | 52 |

| M18*2.50 | M18 | 2.5 | 14 | 11 | 15.5 | 100 | 30 | 55 |

| M20*2.50 | M20 | 2.5 | 15 | 12 | 17.5 | 105 | 32 | 58 |

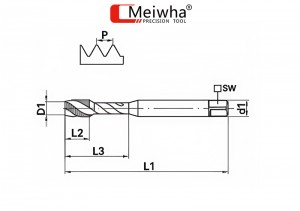

Tap troellog Meiwha JIS:

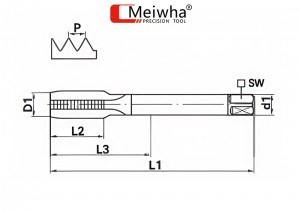

| D1 | P(mm) | d1(mm) | SW | L1(mm) | L2(mm) | L3(mm) | Rhif o ffliwt | TAP goddefgarwch |

| M3 | 0.5 | 4.0 | 3.2 | 46 | 10.0 | 19 | 3 | 6H |

| M4 | 0.7 | 5.0 | 4.0 | 52 | 8.4 | 20 | 3 | 6H |

| M5 | 0.8 | 5.5 | 4.5 | 60 | 9.6 | 24 | 3 | 6H |

| M6 | 1.0 | 6.0 | 4.5 | 62 | 12.0 | 29 | 3 | 6H |

| M8 | 1.0 | 6.2 | 5.0 | 70 | 15.0 | 37 | 3 | 6HX |

| M8 | 1.25 | 6.2 | 5.0 | 70 | 15.0 | 37 | 3 | 6H |

| M10 | 1.0 | 7.0 | 5.5 | 75 | 18.0 | 41 | 3 | 6HX |

| M10 | 1.25 | 7.0 | 5.5 | 75 | 18.0 | 41 | 3 | 6HX |

| M10 | 1.5 | 7.0 | 5.5 | 75 | 18.0 | 41 | 3 | 6H |

| M12 | 1.25 | 8.5 | 6.5 | 82 | 18.0 | 48 | 3 | 6H |

| M12 | 1.5 | 8.5 | 6.5 | 82 | 18.0 | 48 | 3 | 6H |

| M12 | 1.75 | 8.5 | 6.5 | 82 | 18.0 | 48 | 3 | 6H |

| M14 | 1.5 | 10.5 | 8.0 | 88 | 20.0 | 48 | 3 | 6HX |

| M14 | 2.0 | 10.5 | 8.0 | 88 | 20.0 | 48 | 3 | 6HX |

| M16 | 1.5 | 12.5 | 10.0 | 95 | 20.0 | 52 | 3 | 6HX |

| M16 | 2.0 | 125 | 10.0 | 95 | 20.0 | 52 | 3 | 6HX |

| M18 | 1.5 | 14.0 | 11.0 | 100 | 25.0 | 55 | 4 | 6HX |

| M18 | 2.5 | 14.0 | 11.0 | 100 | 25.0 | 55 | 4 | 6HX |

| M20 | 1.5 | 15.0 | 12.0 | 105 | 25.0 | 58 | 4 | 6HX |

| M20 | 2.5 | 15.0 | 12.0 | 105 | 25.0 | 58 | 4 | 6HX |

| M24 | 3.0 | 19.0 | 15.0 | 120 | 30.0 | 66 | 4 | 6HX |

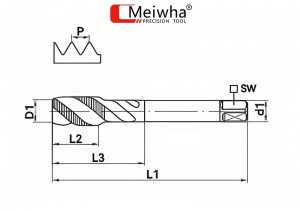

Tap troellog Meiwha DIN371:

| D1 | P(mm) | d1(mm) | SW | L1(mm) | L2(mm) | L3(mm) | Rhif o ffliwt | TAP goddefgarwch |

| M3 | 0.5 | 3.5 | 2.7 | 56 | 10.0 | 18 | 3 | 6H |

| M4 | 0.7 | 4.5 | 3.4 | 63 | 8.4 | 21 | 3 | 6H |

| M5 | 0.8 | 6.0 | 4.9 | 70 | 9.6 | 25 | 3 | 6H |

| M6 | 1.0 | 6.0 | 4.9 | 80 | 12.0 | 30 | 3 | 6H |

| M8 | 1.0 | 8.0 | 6.2 | 90 | 15.0 | 35 | 3 | 6HX |

| M8 | 1.25 | 8.0 | 6.2 | 90 | 15.0 | 35 | 3 | 6H |

| M10 | 1.0 | 10.0 | 8.0 | 100 | 18.0 | 39 | 3 | 6HX |

| M10 | 1.25 | 10.0 | 8.0 | 100 | 18.0 | 39 | 3 | 6HX |

| M10 | 1.5 | 10.0 | 8.0 | 100 | 18.0 | 39 | 3 | 6H |

Tap troellog Meiwha DIN376:

| D1 | P(mm) | d1(mm) | SW | L1(mm) | L2(mm) | L3(mm) | Rhif o ffliwt | TAP goddefgarwch |

| M12 | 1.25 | 9.0 | 7.0 | 110 | 18.0 | -- | 3 | 6H |

| M12 | 1.5 | 9.0 | 7.0 | 110 | 18.0 | -- | 3 | 6H |

| M12 | 1.75 | 9.0 | 7.0 | 110 | 18.0 | -- | 3 | 6H |

| M14 | 1.5 | 11.0 | 9.0 | 110 | 20.0 | -- | 3 | 6HX |

| M14 | 2.0 | 11.0 | 9.0 | 110 | 20.0 | -- | 3 | 6HX |

| M16 | 1.5 | 12.0 | 9.0 | 110 | 20.0 | -- | 3 | 6HX |

| M16 | 2.0 | 12.0 | 9.0 | 110 | 20.0 | -- | 3 | 6HX |

| M18 | 1.5 | 14.0 | 11.0 | 125 | 25.0 | -- | 4 | 6HX |

| M18 | 2.5 | 14.0 | 11.0 | 125 | 25.0 | -- | 4 | 6HX |

| M20 | 1.5 | 16.0 | 12.0 | 140 | 25.0 | -- | 4 | 6HX |

| M20 | 2.5 | 16.0 | 12.0 | 140 | 25.0 | -- | 4 | 6HX |

| M24 | 3.0 | 18.0 | 14.5 | 160 | 30.0 | -- | 4 | 6HX |

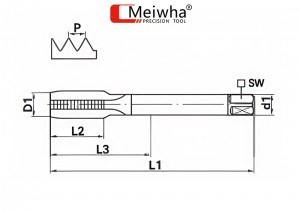

Tap ffliwt syth Meiwha JIS

| D1 | P(mm) | d1(mm) | SW | L1(mm) | L2(mm) | L3(mm) | Rhif o ffliwt | TAP goddefgarwch |

| M6 | 1.0 | 6.0 | 4.5 | 62 | 16.0 | 29 | 4 | 6HX |

| M8 | 1.0 | 6.2 | 5.0 | 70 | 21.0 | 37 | 4 | 6HX |

| M8 | 1.25 | 6.2 | 5.0 | 70 | 21.0 | 37 | 4 | 6HX |

| M10 | 1.0 | 7.0 | 5.5 | 75 | 23.0 | 41 | 4 | 6HX |

| M10 | 1.25 | 7.0 | 5.5 | 75 | 23.0 | 41 | 4 | 6HX |

| M10 | 1.5 | 7.0 | 5.5 | 75 | 23.0 | 41 | 4 | 6HX |

| M12 | 1.25 | 8.5 | 6.5 | 82 | 24.0 | 48 | 4 | 6HX |

| M12 | 1.5 | 8.5 | 6.5 | 82 | 24.0 | 48 | 4 | 6HX |

| M12 | 1.75 | 8.5 | 6.5 | 82 | 24.0 | 48 | 4 | 6HX |

| M14 | 1.5 | 10.5 | 8.0 | 88 | 24.0 | 48 | 4 | 6HX |

| M14 | 2.0 | 10.5 | 8.0 | 88 | 24.0 | 48 | 4 | 6HX |

| M16 | 1.5 | 12.5 | 10.0 | 95 | 24.0 | 52 | 4 | 6HX |

| M16 | 2.0 | 12.5 | 10.0 | 95 | 24.0 | 52 | 4 | 6HX |

| M18 | 1.5 | 14.0 | 11.0 | 100 | 24.0 | 55 | 4 | 6HX |

| M18 | 2.5 | 14.0 | 11.0 | 100 | 24.0 | 55 | 4 | 6HX |

| M20 | 1.5 | 15.0 | 12.0 | 105 | 26.0 | 58 | 4 | 6HX |

| M20 | 2.5 | 15.0 | 12.0 | 105 | 26.0 | 58 | 4 | 6HX |

Tap ffliwt syth Meiwha DIN371

| D1 | P(mm) | d1(mm) | SW | L1(mm) | L2(mm) | L3(mm) | Rhif o ffliwt | TAP goddefgarwch |

| M3 | 0.5 | 3.5 | 2.7 | 56 | 10.0 | 18 | 3 | 6HX |

| M4 | 0.7 | 4.5 | 3.4 | 63 | 13.0 | 21 | 3 | 6HX |

| M5 | 0.8 | 6.0 | 4.9 | 70 | 16.0 | 25 | 3 | 6HX |

| M6 | 1.0 | 6.0 | 4.9 | 80 | 18.0 | 30 | 4 | 6HX |

| M8 | 1.0 | 8.0 | 6.2 | 90 | 20.0 | 35 | 4 | 6HX |

| M8 | 1.25 | 8.0 | 6.2 | 90 | 20.0 | 35 | 4 | 6HX |

| M10 | 1.0 | 10.0 | 8.0 | 100 | 20.0 | 39 | 4 | 6HX |

| M10 | 1.25 | 10.0 | 8.0 | 100 | 20.0 | 39 | 4 | 6HX |

| M10 | 1.5 | 10.0 | 8.0 | 100 | 20.0 | 39 | 4 | 6HX |

Tap ffliwt syth Meiwha DIN376

| D1 | P(mm) | d1(mm) | SW | L1(mm) | L2(mm) | L3(mm) | Rhif o ffliwt | TAP goddefgarwch |

| M3 | 0.5 | 3.5 | 2.7 | 56 | 10.0 | 18 | 3 | 6HX |

| M4 | 0.7 | 4.5 | 3.4 | 63 | 13.0 | 21 | 3 | 6HX |

| M5 | 0.8 | 6.0 | 4.9 | 70 | 16.0 | 25 | 3 | 6HX |

| M6 | 1.0 | 6.0 | 4.9 | 80 | 18.0 | 30 | 4 | 6HX |

| M8 | 1.0 | 8.0 | 6.2 | 90 | 20.0 | 35 | 4 | 6HX |

| M8 | 1.25 | 8.0 | 6.2 | 90 | 20.0 | 35 | 4 | 6HX |

| M10 | 1.0 | 10.0 | 8.0 | 100 | 20.0 | 39 | 4 | 6HX |

| M10 | 1.25 | 10.0 | 8.0 | 100 | 20.0 | 39 | 4 | 6HX |

| M10 | 1.5 | 10.0 | 8.0 | 100 | 20.0 | 39 | 4 | 6HX |

Ysgrifennwch eich neges yma a'i hanfon atom ni